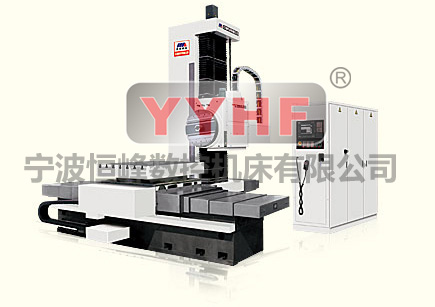

CNC Gantry Boring and Milling Machine: Expressing Excellent Quality in Rapid Development

[China Machine Tool Business Network Technology Trends] In the past two years, China's CNC gantry boring and milling machines have developed rapidly. At present, the CNC gantry boring and milling machine independently developed and developed by China has basically met the needs of some national key projects and has repeatedly created the world's largest limit specification.

Beijing No.1 Machine Tool Plant began to manufacture super heavy-duty CNC gantry boring and milling machines with the largest single unit output value (87 million yuan/set) in China. A group of the world's most advanced heavy-duty machine tools have been put into development one after another, which will guide China into the world's largest manufacturing base of heavy machine tool manufacturers. Column.

Wuhan Heavy Machine Tool Group made XKD super heavy-duty CNC double boring and milling machine and put it into use. The machine is a double gantry mobile, 4 milling head, gantry width 6.8m, processing length 57m. Shuanglongmen mobile 4 milling head structure is a domestic initiative.

The development of CNC boring and milling machines and the new design concept lead the trend of modern machining. The ram-less type with high-speed machining and the structure type used for the exchange of various milling heads make full use of the style, which greatly replaces traditional milling machining. the trend of. The various milling head attachments represented by the two-axis swivel heads are the main means for realizing high-speed, high-efficiency composite machining. The process performance is wider, the power is greater, and the rigidity is stronger.

CNC gantry boring and milling machine main performance characteristics:

1. The main milling head adopts a ram-deceleration box separated design to improve the precision of the milling head. The gear box adopts a two-speed gear automatic transmission mechanism to obtain low-speed high-torque and high-speed constant power, which can simultaneously satisfy rough machining and precision. Processing process requirements.

2. High-precision spindle combination bearings ensure the high performance and high precision of the main milling head. The ram milling head is also balanced with hydraulic cylinders for smooth motion.

3, three-axis transmission are imported high precision preloaded ball screw or dual gear - rack no gap transmission, thus ensuring the transmission accuracy.

4. Three-axis feedback adopts photoelectric encoder to achieve semi-closed loop position feedback, and can also use grating ruler to achieve full closed-loop position feedback according to user requirements.

The CNC boring and boring and milling machine meets the requirements for the processing of super-large parts in the areas of aerospace, power generation equipment, and automobiles; high-speed precision CNC lathes and processing middle products are widely used in various occupational areas such as automotive, aerospace, electronics, and military. It has also brought about a lot of equipment upgrades and industrial upgrading of small and medium-sized companies.

The daily maintenance of CNC boring and milling machines is also very critical. Many common faults are caused by ignoring routine maintenance. If the CNC gantry boring and milling machines are used, follow the scientific operation guidelines and routine maintenance rules and regulations. Avoid many problems and reduce the economic loss.

CNC boring and milling machine is an advanced processing equipment with high automation, complicated structure and high price. Play a huge role in modern industrial production. In order to give full play to the effectiveness of CNC milling machine, do a good job of daily maintenance and maintenance of the machine tool. It is very important to reduce the failure rate of CNC boring mills.

The overall structure of the CNC gantry boring and milling machine consists of a gantry frame. The gantry frame is composed of double columns, beams, connecting beams, top beams, top covers and milling head rams to form a rigid frame. The beams move up and down along the column guide rails. High-power multi-function ram-type boring and milling head, boring and milling head slide plate along the beam guide left and right movement and its up and down movement, the gantry frame along the bed longitudinal movement.

When operating the CNC boring mill, the operator should be familiar with the specifications of the machine being used. Such as spindle motor power, spindle speed range, feed rate, machine tool travel range, table load capacity, maximum tool size allowed by ATC, maximum tool size, etc. Also need to know the location of each oil standard and the type of lubricant used.

Before operating the machine, you must confirm whether the oil level of the spindle, guide rail and other parts meets the requirements and confirm whether the pressure pressure meets the requirements. After confirming that the requirements are met, start the machine. And let the machine run 3 minutes. Check if the machine is abnormal.

In addition, the surrounding environment of the machine tool should be kept clean, and the CNC boring and milling machine should be regularly dusted so as to avoid poor cooling air passage, causing the temperature in the numerical control cabinet to be too high and the system to not work properly. The circuit board and electrical components inside the electrical cabinet must also be regularly dusted to ensure that the electrical system works properly.